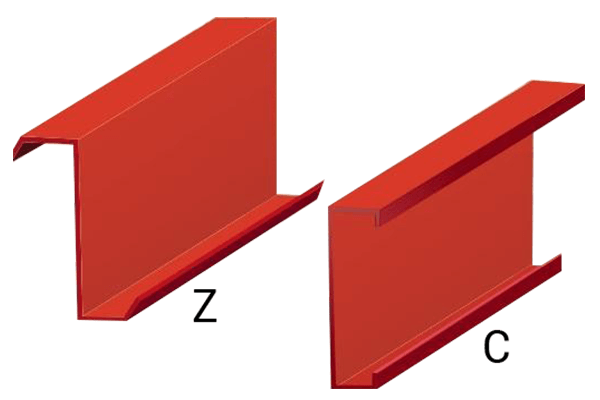

Z and C Purlin / Section

Cladding purlins girts & eve struts are secondary structural members used to support the wall and roof panels. Cladding purlins are used on the roof, girts are used on the walls and eve struts at the intersection of side walls and roofs.

Cladding purlins, girts and eave struts are designed in accordance of the American Iron and Steel Institue (AISI) then cold formed design manual.

Cladding sections may be used over single spans unlapped continuous and lapped continuous span in multi bay buildings.

Cladding Z&C purlins are available in two Standard Finishes i.e., Red Oxide, Galvanized

Why Cladding

Material Specification

-

- IS 513/IS 277/IS 10748/IS 1079

- G240 MPA/G340 MPA/G550 MPA, Z 120 GSM/Z 275 GSM & Z 180 GSM

- G indicates Yield Strength in MPA & Z indicates Coating Mass in G/M2

Steel Grade

-

- Cladding Zed & CEE Purlins with punching

Thickness

- Sleeves

- Cleats

- Sag rods

HR Purlins

-

- Yield Strength – 240 MPA

- Option – Redoxide Primer Coating

GI Purlins

-

-

- Coating Mass – 120 GSM / 180 GSM / 275 GSM

- Yield Strength – 240 MPA / 340 MPA / 550 MPA

-

Application

Advantages

Economy

- Savings in steel consumption upto 50% and savings in cost upto 30%

- Savings of transportation & handling, erection and fabrication costs

- No wastages, No surplus left-overs, since sections are supplied in exact required lengths

Design

- High strength, section versatility & wide range of choice

- Having their shear centre within the section, less liable to twist

Structure

- Sleeve system to exploit continuity concept for larger spans

- Empirical design rules apply, hence no design problems

- Excellent surface finish

- Less weight per unit length compared to conventional section without sacrificing the required structural efficiency

- Conforming to the requirements of IS-801, IS-811

Practical Advantages

- Ability to rotate 180 degrees and fit together

- A full range of fixing accessories is supplied. Therefore no extra material needs be procured

- Sections supplied are pre-painted hence prevents corrosion and promotes long life

- Sections are pre-engineered, pre-punched and with complete accessories. No further fabrication required . Considerable savings in erection costs and time.

Typical Connection

Handling and Storage

- Purlin requires appropriate care during storage on site

- The period between delivery and installation to be minimized

- Purlin should be neatly stacked on a ground on a slight slope so that water can drain out

- On open site condition purlins should be protected with water proof covers and condensation

- In case if the bundle of purlins becomes wet , seprate the purlins and wipe & dry it

Technical Specification

| TECHNICAL SPECIFICATION OF Z AND C | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| purlin DEPTH D | Thickness(t) | Mass(Kg/M) | ZED PURLIN | CEE PUTLIN | |||||

| F | L | F | L | ||||||

| 160 | 2.00 | 4.82 | 60 | 20 | 60 | 20 | |||

| 160 | 2.30 | 5.54 | 60 | 20 | 60 | 20 | |||

| 160 | 2.55 | 6.15 | 60 | 20 | 60 | 20 | |||

| 200 | 2.00 | 5.44 | 60 | 20 | 60 | 20 | |||

| 200 | 2.55 | 6.95 | 60 | 20 | 60 | 20 | |||

| 230 | 2.00 | 5.92 | 60 | 20 | 60 | 20 | |||

| 230 | 2.30 | 6.87 | 60 | 20 | 60 | 20 | |||

| 230 | 2.55 | 7.55 | 60 | 20 | 60 | 20 | |||

| 250 | 2.00 | 6.23 | 60 | 20 | 60 | 20 | |||

| 250 | 2.30 | 7.17 | 60 | 20 | 60 | 20 | |||

| 250 | 2.55 | 7.95 | 60 | 20 | 60 | 20 | |||