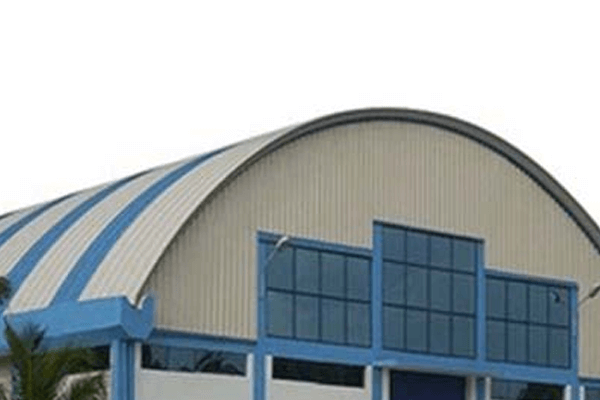

Self Supported Roofing Sheet

The sheets are produced and installed at site without any supports like Trusses, Purlins or any other structural members. It Provides larger enclosed volumes, free movement, effective handling of goods and higher utilization. Self supported roofing sheets have created a revolution in the industry as these roofing sheets do not require any kind of support. Our roofing sheets uses mechanical sealing and installed without any holes, nuts, bolts, overlaps or sealants thus reducing on maintenance cost and maximizing on corrosion resistant property. With no need of making holes, drilling nuts and bolts, the overall time for installation lowers down remarkably thus increasing the efficiency with faster project turnaround.

Self Supported Roofing Sheet

Self Supported Roof Sheet

Self Supported Roofing Sheet

Self supported truss less roofing

- Self supported roofing are manufactured from color coated galvalume/bare galvalume/color coated galvanized coils of thickness from 0.85mm TCT to 1.6mm TCT.

- They are self-supporting roofs and do not require any trusses, purlins or any ancillary supports.

- High standard of thermal insulation

- It is 100% leak proof roof with zero maintenance and free from holes,nuts and bolts.

- The roof has a clear span which can accommodate larger enclosed volumes and is resistant to damage and corrosion.

- It is very aesthetically appealing and maintains cool temperature.

- Birds cannot nest under the truss less roofs.

- Install at on-site installation of approximately 10000 sqft in just 12 hours.

- The roof is sturdy and durable ensuring long life of 25 to 30 years.

- Truss less roofing is preferred because of the clear span up to 35 meters.

- Application- Warehousing,logistic companies, automobile service centers, food processing, manufacturing, textiles,chemicals,pharma,defence structures and air craft hangers.

- Auditoriums, exhibition halls, conventional centers etc.

Raw materials used:

- Color coated steel structural grade in coil form.

- Steel grade 300 mpa YS min.

- Steel thickness from 0.85mm to 1.6mm TCT( Total coating thickness).

- As per ASTN A 792/A755 steel sheet/Aluminum –Zinc alloy.

- Hot dipped galvanized or galvalume materials used.

- Galvanized- 120 gsm or Galvalume AZ 150 as per customer specification.

- Coil width 914mm,sheet width 610mmwith tolerance of thickness + or – 0.03mm.

Roofing Designs

- Curved designs as per client requirements.

- Roofing can be done over the RCC structure which is the commonly used one as per customer’s design and requirements.

- Roofing can also be done over steel structures.

- Elevated base,L-section roofs, Half arch, Multiple bays, Differential heights structures, Ground to ground ( as per below drawings).

Accessories

- Gutters and down pipes

- Sky lights

- Turbo ventilators

- Light hangers